Analysis Report on Sunwoda's Battery Safety Issues and Quality Control System Vulnerabilities

Unlock More Features

Login to access AI-powered analysis, deep research reports and more advanced features

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.

Related Stocks

Based on the collected materials, I will provide you with an in-depth analysis report on Sunwoda’s battery safety issues and quality control system vulnerabilities.

December 26, 2025, Sunwoda (300207.SZ) issued an announcement disclosing that its subsidiary Sunwoda Power was sued by Viridi E-Mobility Technology Co., Ltd. (51% owned by Zeekr) under Geely Holding Group, with a claim amount of up to

- Timeframe: Battery cells delivered between June 2021 and December 2023 have quality defects

- Involved Models: Zeekr 001 WE86 version (approximately 40,000-50,000 units)

- Quality Issues: Abnormally slow charging speed, abnormal battery capacity fading, false range claims

Affected by this news, Sunwoda’s stock price plummeted 11.39% in a single day, with its market value evaporating approximately RMB 6.3 billion[3].

In January 2026, Volvo Cars launched a global recall of the 2025 EX30 model, involving approximately 40 vehicles produced between September 2024 and October 2025[4].

| Item | Details |

|---|---|

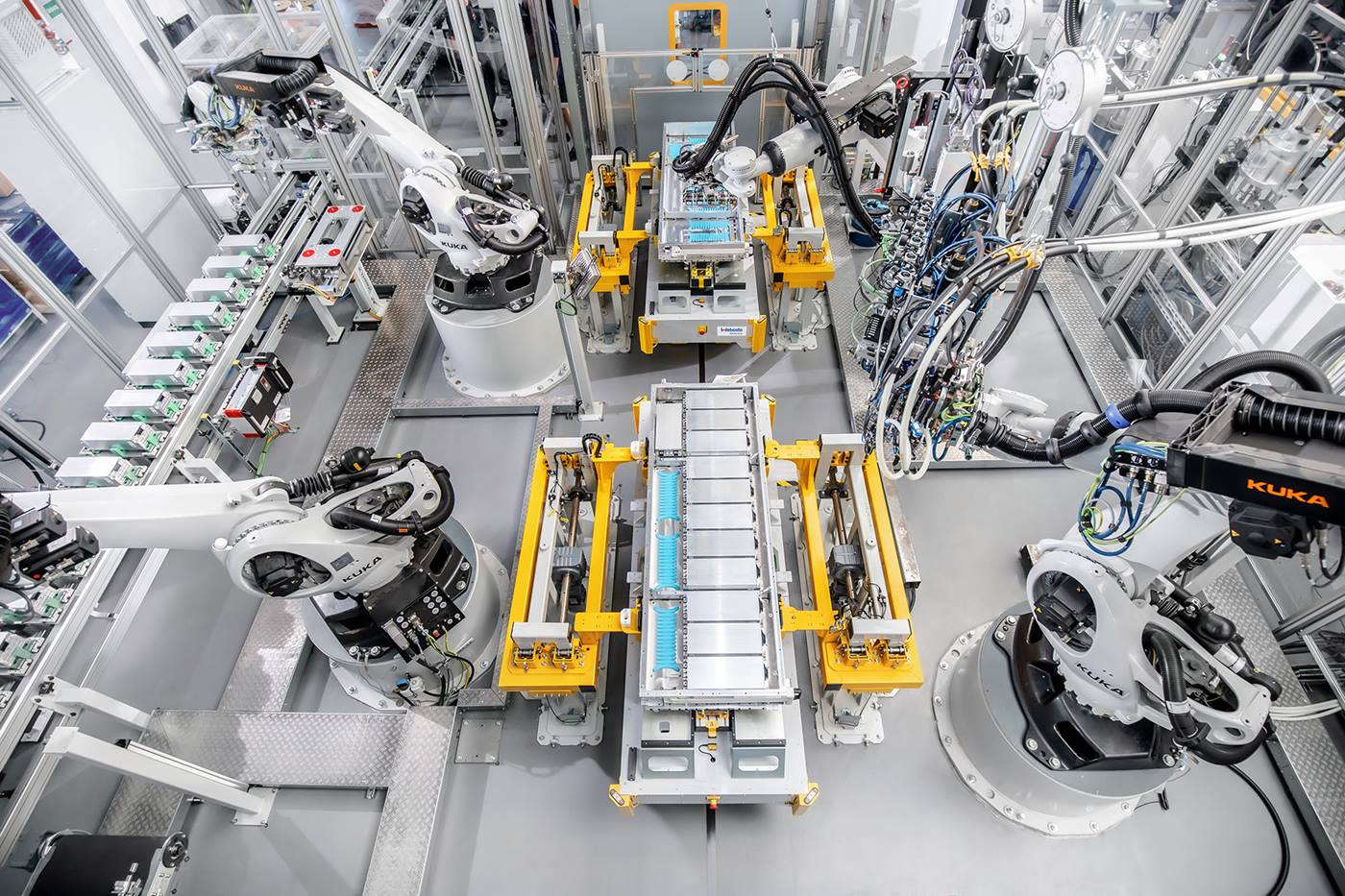

| Recall Reason | Manufacturing process deviations exist in Sunwoda’s battery cells |

| Defect Manifestation | Lithium plating (dendrites) forms inside the battery, which may cause short circuits and overheating |

| Interim Measure | Limit charging to 70% capacity, prohibit indoor parking |

| Estimated Defect Rate | 100% of affected vehicles have the defect |

According to internal materials of Sunwoda Power Technology, its quality management system has the following significant vulnerabilities[5]:

- When a certain number of abnormal issues accumulate daily, they cannot be effectively tracked and closed

- Difficult to trace historical issues, lack of systematic problem file management

- Unclear issue escalation process, timeliness cannot be guaranteed

- Quality issues occur and are resolved on the production site

- The quality issue management system is on the office intranet

- Lack of a unified platform connecting information data chains, leading to information silos

- Cannot efficiently identify and resolve abnormal issues

- Slow resource mobilization response speed

- Severe flaws exist in issue follow-up and escalation mechanisms

According to documents submitted by Volvo to the National Highway Traffic Safety Administration (NHTSA), Sunwoda’s battery cells have

- Continues to grow over time

- May penetrate the separator and cause internal short circuits

- May trigger battery fire risks in extreme cases

According to industry analysis, some batches of cells delivered by Sunwoda have the following issues[2]:

- Inconsistent voltage platforms: Significant performance differences among cells in the same battery pack

- Excessive internal resistance differences: Lead to uneven charging efficiency and accelerated battery fading

- Abnormal capacity fading curve: Some cells age and fail prematurely

Against the backdrop of the battery industry’s frantic expansion, quality control has become a casualty[3]:

| Issue Dimension | Specific Performance |

|---|---|

| Too rapid technology iteration | Each battery technology iteration means a brand-new production process and quality control system |

| Compressed verification time | The surging demand from downstream automakers has significantly compressed the verification cycle of battery products |

| Sacrificed quality control | In the race to be “faster and stronger”, quality control is subordinated to speed |

- 2020 domestic power battery output: 83.4GWh

- 2024 domestic power battery output: 826GWh

- Output nearly increased 10-fold in 4 years[3]

Major manufacturers have aggressively expanded production with a “scale competition” mindset, scrambling for customer resources, leading some enterprises to ignore battery quality issues.

Changes in average energy storage system prices:

- 2022: RMB 1.5/Wh

- 2025: RMB 0.5/Wh

- Decline of over 66%

Under cost reduction pressure, some enterprises cut corners to reduce costs, breaking through the quality bottom line[3].

According to Sunwoda’s official Code of Conduct, its claimed quality control measures include[6]:

| Official Statement | Actual Implementation |

|---|---|

| Non-conforming product control process | The Volvo recall incident shows that non-conforming products entered the market |

| Hazardous substance management and label traceability | Imperfect traceability mechanism, difficult to trace historical issues |

| Advanced tools such as Lean Six Sigma and QCC | There is still over 60% room for improvement in issue response efficiency |

| Continuous improvement mechanism | Quality issues still occur frequently |

In the prospectus submitted by Sunwoda to the Hong Kong Stock Exchange (HKEX), the company clearly disclosed the following quality risks[7]:

-

Risk of effectiveness of quality control system: The effectiveness of the quality control system depends on system design, quality standard implementation, employee training and compliance

-

Consequences of possible product defects:

- Returns, order cancellations, customer complaints

- Product recalls and high costs

- Damaged brand reputation

- Government investigations and stricter regulation

-

Risk of manufacturing process complexity:

- Complex equipment requires regular adjustment and upgrading

- New manufacturing process technologies may cause production difficulties

- Delivery delays or reduced output

| Impact Dimension | Specific Performance |

|---|---|

Financial Impact |

The RMB 2.314 billion claim is equivalent to two years of net profit, and the company may need to accrue a provision for contingent liabilities |

Listing Impact |

Its Hong Kong stock listing application submitted in July 2025 may be affected |

Customer Impact |

Existing customers (Li Auto, XPeng, Volkswagen, etc.) may re-evaluate their cooperative relationships |

Brand Impact |

Consumer trust in second-tier battery manufacturers declines |

- Redefined Supply Chain Responsibilities: Automakers are no longer willing to bear the quality “blame” for core three-electric systems alone, and are shifting to legal means to hold upstream suppliers accountable

- Breaking Unwritten Rules: This lawsuit breaks the traditional resolution model of “private negotiation, discounted supply” in the new energy vehicle industry

- Upgraded Quality Standards: Standards jointly issued by seven ministries including the State Administration for Market Regulation have listed “no fire, no explosion” as a mandatory technical requirement[3]

- Survival Challenges for Second-Tier Battery Manufacturers: Brand “deficits” need to be compensated with more hidden costs, and consumers have obvious concerns about models using Sunwoda batteries

The frequent occurrence of Sunwoda’s battery safety issues exposes the

- Manufacturing Process Control: Process deviations in production were not detected before leaving the factory, leading to defective cells entering the market

- Problem Response Mechanism: Imperfect internal issue handling processes, low response efficiency, and inability to quickly close quality anomalies

- Lack of Traceability System: Lack of full-life-cycle quality traceability capability, making it difficult to analyze causes and determine responsibilities after issues occur

- Disconnection Between System and Implementation: Obvious gap between the officially claimed quality management system and actual implementation

This incident is not only a quality issue for Sunwoda as an individual, but also a microcosm of the concentrated outbreak of long-standing quality issues left over from the rapid expansion period of the new energy vehicle industry. With tighter regulation and deeper consumer awareness, battery safety and quality control will become the key bottom line for enterprise survival.

[4] Carscoops - Volvo Warns 40 EV Owners To Park Outside Now

[6] Sunwoda Official Website - Sunwoda Electronic Co., Ltd. Code of Conduct

Insights are generated using AI models and historical data for informational purposes only. They do not constitute investment advice or recommendations. Past performance is not indicative of future results.

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.