Sunwoda's RMB 2.3 Billion Sky-High Claim: In-Depth Analysis of Expansion Predicaments and Quality Crises Among Second-Tier Battery Manufacturers

Unlock More Features

Login to access AI-powered analysis, deep research reports and more advanced features

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.

Related Stocks

Based on search results, I have obtained detailed information about Sunwoda’s quality control issues and the expansion predicaments of second-tier battery manufacturers. Let me provide an in-depth analysis for you.

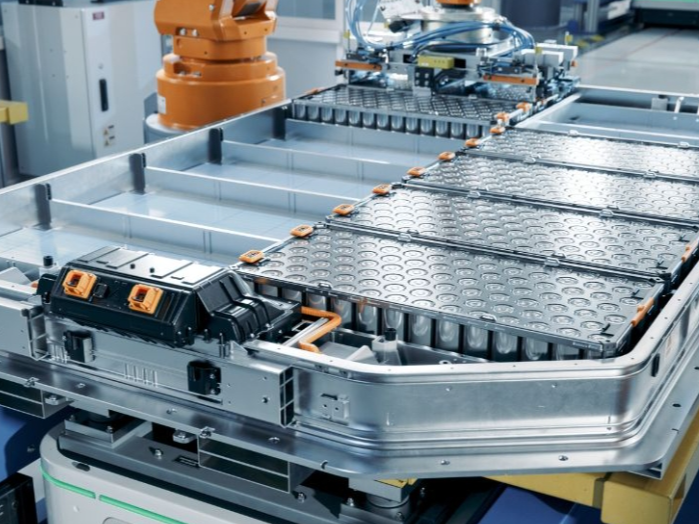

On December 26, 2025, Sunwoda (Stock Code: 300207) issued an announcement disclosing that its wholly-owned subsidiary Sunwoda Power has been officially sued by Viridi E-Mobility under Geely Holding, with a claim amount as high as RMB 2.314 billion [1][2]. This claim stems from quality issues alleged in the battery cells supplied by Sunwoda to Zeekr and other models between June 2021 and December 2023, which led to large-scale battery pack replacements by Viridi E-Mobility.

- Second half of 2022: Owner complaints about relevant quality issues emerged

- 2024: Zeekr launched a battery pack replacement campaign

- August 2024: Sunwoda Power once sued Viridi for overdue payment of RMB 119 million and won the case

- December 26, 2025: Viridi E-Mobility officially sued Sunwoda

Affected by this news, Sunwoda’s stock price plummeted 11.39% on December 29, with its market value evaporating over RMB 6.3 billion in a single day [1][2]. More seriously, this lawsuit occurred during Sunwoda’s critical period of promoting its “A+H” overall listing, and its Hong Kong IPO plan may face major uncertainties.

The Sunwoda incident is by no means an isolated case, but exposes the systemic predicaments faced by the entire group of second-tier battery manufacturers amid rapid expansion.

Each battery technology iteration means a brand-new production process and quality control system. However, the rapid expansion of downstream automakers’ demand has drastically compressed battery product validation time. In the race to be “faster and stronger”, quality control often falls victim [1].

In 2020, domestic power battery output was 83.4GWh, and by 2024 it reached 826GWh, nearly 10 times growth in just 4 years [1]. Major manufacturers are expanding massively with a “scale competition” mindset:

- Sunwoda: Announced multiple expansion projects in 2021 with a total investment of RMB 45 billion, adding 90GWh of capacity, and planning to reach 140GWh by 2025

- SVOLT Energy: Plans to raise its global capacity target to 600GWh by 2025

- CALB: Plans to exceed 500GWh of capacity by 2025, and target 1TWh by 2030

This aggressive expansion has left quality system construction behind.

The average price of energy storage systems dropped from RMB 1.5/Wh in 2022 to around RMB 0.5/Wh in 2025 [1]. Against the backdrop of fierce price wars, cutting corners has become an “unspoken” choice for some enterprises.

The current Chinese power battery market presents a “two superpowers, multiple strong players” structure:

- CATL: Approximately 43% market share

- BYD: Approximately 23% market share

- Combined share of the two giants: Over 65% market share

Remaining players can only compete for less than one-third of the market space [3][4].

Second-tier manufacturers are generally trapped in the situation of “losing more as they sell more”:

| Company | H1-H3 2025 Status |

|---|---|

Sunwoda Power |

Accumulated losses of over RMB 3.4 billion in the past two years |

EVE Energy |

Rapid revenue growth, but net profit excluding non-recurring items dropped by over 22% |

Gotion High-Tech |

After excluding investment gains from Chery’s equity, core business profit was less than RMB 100 million |

CALB |

Profit scale of approximately RMB 690 million, over 70 times smaller than CATL’s |

SVOLT Energy |

Accumulated losses of over RMB 3 billion from H1 2019 to H1 2022 |

Although Sunwoda Group as a whole is profitable (annual revenue exceeding RMB 50 billion), its power battery business is actually a “profit black hole” that needs to be “blood-transfused” by its consumer battery business [3][4].

Second-tier manufacturers generally have gross margins suppressed below 20%, a significant gap compared to CATL’s stable level of over 25% [3]. Meager profits in turn restrict sustained high investment in R&D and quality control, forming a vicious cycle.

Sunwoda is not an isolated case; battery quality issues have occurred frequently in recent years:

| Year | Incident | Responsible Party |

|---|---|---|

| 2020 | WM Motor EX5 spontaneous combustion due to impurities in battery cells | ZTE High Energy |

| 2021 | BAIC Group recalled over 30,000 electric vehicles | Farasis Energy |

| 2024 | Mercedes-Benz EQE350 spontaneous combustion in an underground parking lot in South Korea | Farasis Energy |

| 2025 | Li Auto MEGA recalled 11,411 units | Li Auto/Suppliers |

International giants are also not immune to quality issues:

- 2020: Samsung SDI caused Ford and BMW to recall over 50,000 vehicles globally due to battery cell process issues

- 2021: LG Energy Solution compensated Hyundai Motor and General Motors RMB 17.8 billion for battery defects

The energy storage sector is even a disaster zone for incidents; as of May 2025, 167 energy storage fire and explosion incidents have occurred worldwide [1].

The division of quality responsibilities for power batteries is far more complex than it appears. When batch performance issues occur in battery packs, the responsibility may stem from the battery cells themselves, or from battery pack design, BMS management strategies, or vehicle assembly processes [5]. In the lawsuit between Sunwoda and Viridi, Sunwoda argued that it only supplied battery cells, while the battery packs were designed by Viridi itself, and the same type of battery cells supplied to other customers did not have similar problems.

Li Auto once adopted a dual-supplier strategy of CATL + Sunwoda, but a large number of concerns about Sunwoda batteries appeared on social platforms, with some consumers explicitly requesting “no Sunwoda batteries” [1]. As the “heart” of electric vehicles, batteries are directly related to brand reputation and user safety, and automakers have almost zero tolerance for supply chain safety issues.

Fortunately, regulatory authorities have begun to address battery quality and safety issues. The “Action Plan for Promoting Equipment Renewal and Consumer Goods Trade-In Driven by Standard Upgrades”, jointly issued by seven ministries including the State Administration for Market Regulation, has made a major breakthrough by listing “no ignition, no explosion” as a mandatory technical requirement for the first time [1].

Sunwoda’s RMB 2.3 billion claim has indeed torn open the “quality abscess” of second-tier battery manufacturers’ expansion, exposing the following common problems:

- Prioritizing scale over quality: Aggressive expansion has led to lagging quality system construction

- Prioritizing speed over validation: Technological iteration has compressed necessary validation cycles

- Prioritizing cost over safety: Amid price war pressures, quality control is subordinated to cost control

- Prioritizing market share over profits: Amid the oligopoly of giants, second-tier manufacturers are forced to exchange price for volume

- The power battery industry is entering an “elimination round” stage; capacity expansion is not just a scale contest, but a comprehensive test of technical reliability, quality consistency, and customer trust

- Establishing a data-based quality traceability system will be key for the industry to avoid similar disputes

- Stricter supervision will accelerate industry reshuffling, and enterprises with technology and adherence to safety red lines will gain more development space

This RMB 2.3 billion claim is not only a test for Sunwoda, but also a survival test for the entire group of second-tier battery manufacturers. On the balance beam between speed and quality, only by solidifying the foundation of quality can expansion be meaningful.

[1] 36Kr - Sunwoda Hit with RMB 2.3 Billion Sky-High Claim, Tearing Open the “Quality Abscess” Amid Fierce Battery Industry Involution (https://m.36kr.com/p/3628698496676613)

[2] CNfol.com - A RMB 2.3 Billion Stress Test: Sunwoda’s Reflection on the “Balance Beam” (http://mp.cnfol.com/28928/article/1767665347-142199059.html)

[3] 21st Century Business Herald - Second-Tier Battery Factories: Living in the Shadow of Giants (https://www.21jingji.com/article/20260109/herald/7ef83bf2044199131d7dec6289e5cd9c.html)

[4] The Paper - Second-Tier Battery Factories: Living in the Shadow of Giants (https://m.thepaper.cn/newsDetail_forward_32348982)

[5] 21st Century Business Herald - The RMB 2.3 Billion Claim: How Will the Showdown Between Sunwoda and Geely Rewrite Battery Industry Rules? (https://www.21jingji.com/article/20251231/herald/86b593d06e329e4d1e9f1db7060b952e.html)

Insights are generated using AI models and historical data for informational purposes only. They do not constitute investment advice or recommendations. Past performance is not indicative of future results.

About us: Ginlix AI is the AI Investment Copilot powered by real data, bridging advanced AI with professional financial databases to provide verifiable, truth-based answers. Please use the chat box below to ask any financial question.